At Dynamic Conveyor we are committed to quality and low cost of ownership on conveyor systems. For thirty years, we’ve designed and built custom conveyor solutions using components that contribute to longevity and reduced maintenance costs. One of the key parts of our conveyor systems is tensionless belts.

A tensionless conveyor belt, also known as a zero-tension belt, is a type of conveyor belt that uses a unique construction method to eliminate tension in the belt. Traditional conveyor belts rely on tension to keep the belt’s shape and to keep it running. However, tension can cause wear and tear on the belt, reduce its lifespan, and lead to costly maintenance and downtime.

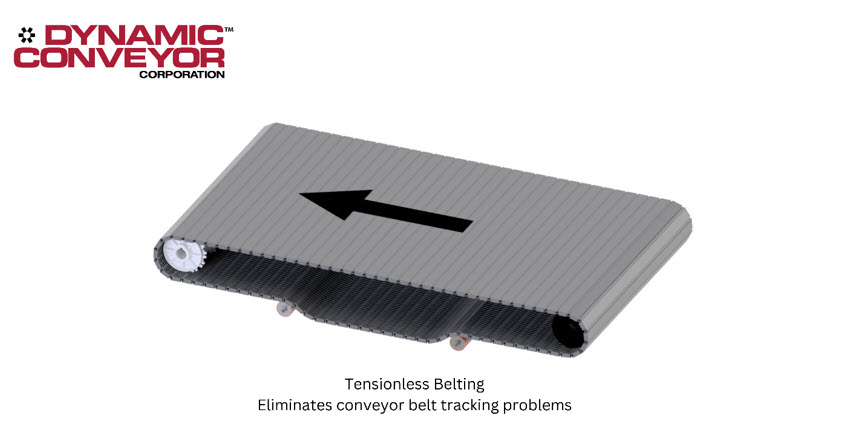

Tensionless conveyor belts are driven by a sprocket system that supplies a positive drive for the belt, ensuring that it moves smoothly and consistently without slipping. The belt is guided around the sprocket which allows it to conform to the shape of the sprockets and positively engages the teeth of the sprocket without stretching or tensioning.

These belts are typically made from materials like polypropylene, polyethylene, or acetal, and are commonly used in applications where a flat, smooth, and durable surface is needed, such as in the industries served by Dynamic Conveyor – food processing, packaging, and manufacturing.

The main reasons Dynamic Conveyor manufactures conveyor systems using tensionless belts are:

- Reduced maintenance: One of the biggest benefits to tensionless belts is that they do not need to be tracked so they eliminate conveyor belt tracking problems. This allows for less maintenance and upkeep with the conveyors. In addition, tensionless belt conveyors have less drive and feed end components than a tension belt conveyor, minimizing maintenance and cost for part replacement. This means that they can be installed and left alone for longer periods of time, resulting in reduced downtime and maintenance costs.

- Longer belt life: Tensionless belts have a longer life span than traditional conveyor belts because they are not subjected to the same amount of stress and tension. This means that they are less likely to tear or experience premature wear, which can again reduce maintenance costs and downtime.

- Increased energy efficiency: Due to less stress or force in the system, we can use more energy efficient motors, resulting in a more cost-effective and sustainable conveyor solution.

- Easy to fix or replace: If the belt is damaged, a tensionless belt allows for the replacement of sections or pieces of the belt when damaged and would not require the replacement of the entire belt, which adds to maintenance costs. This can add up to huge cost savings in just a few repairs.

Overall, tensionless belts eliminate belt tracking problems and have several advantages over traditional conveyor belts, including reduced maintenance and longer belt life. Whatever your operational challenges, contact Dynamic Conveyor to ask how our conveyor solutions could meet your needs.

[starbox]