Sustainable conveyors play a crucial role in promoting environmental responsibility and resource efficiencies in the manufacturing industry. The design, production, and operation of conveyors in a manner that minimizes their environmental impact and maximizes their positive environmental and economic benefits contribute to building a greener future in manufacturing. Considering the entire life cycle of the conveyors in manufacturing use, maintenance and eventual disposal or recycling is key to meeting sustainability initiatives.

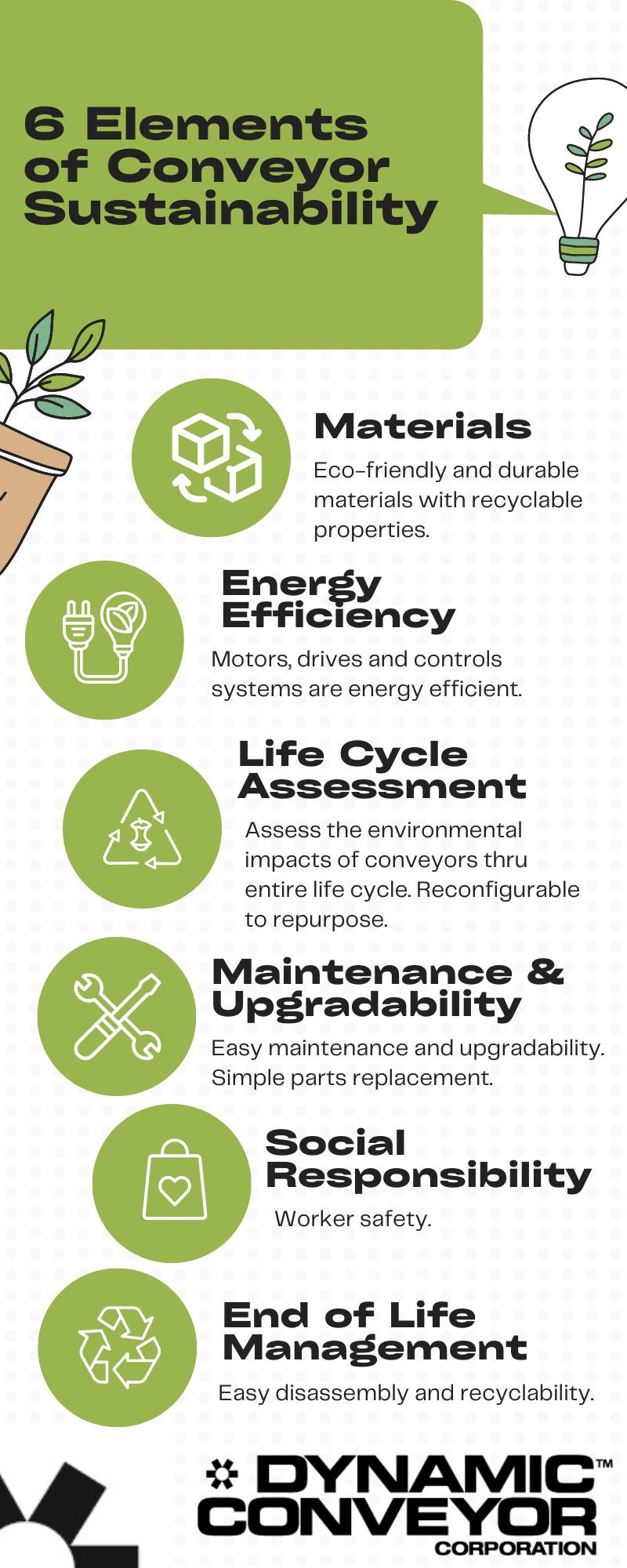

These are important considerations for sustainable conveyors:

Material Selection: Sustainable conveyors starts with the choice of eco-friendly and durable materials. Choosing materials that are “eco-friendly” with a low environmental impact includes materials that can be recycled, or the use of recycled materials and helps reduce the carbon footprint associated with conveyor production and disposal. Additionally, using durable materials ensures the longevity of the conveyors, reducing the need for frequent replacements. Dynamic Conveyor equipment is constructed with durable industrial plastics like polycarbonate, HDPE, UHMW, high density polyethylene, stainless steel, and aluminum. Many of which are exceptionally durable and recyclable.

Energy Efficiency: Energy-efficient conveyor systems are designed to minimize power consumption during operation. This can be achieved using energy-efficient motors, variable speed drives, and advanced control systems that optimize energy usage. By reducing energy consumption, sustainable conveyors help lower greenhouse gas emissions and decrease reliance on fossil fuels. Most often DC Brushless motors are selected for Dynamic Conveyor equipment over AC motors because they reduce power consumption by 30%.

Incorporating modular designs allows for the reconfiguration and repurposing of conveyors or entire conveyance systems in many applications. This allows for waste reduction and considerable cost savings to Manufacturers. Standardized components allow for easier upgrades and replacements, reducing waste generation and resource consumption. Most of the Dynamic Conveyor lines are designed with modularity in mind providing reconfigurability, for those ever-changing plant layouts that gives end users agility in their manufacturing operation and the ability to repurpose conveyors systems as the operation changes.

Life Cycle Assessment (LCA): Conducting a life cycle assessment allows manufacturers to evaluate the environmental impact of their conveyors throughout their entire life cycle. This assessment considers factors such as manufacturing processes, efficiency impacts, and end-of-life disposal. By finding areas of high environmental impact, manufacturers can implement improvements and make informed decisions to enhance sustainability. The modularity and reconfigurability of a conveyor creates the opportunity to repurpose and extend the life cycle.

Maintenance: Sustainable conveyors are designed to require minimal & simple maintenance. Systems that are regularly maintained with little effort help extend the lifespan of the conveyor system, reducing the need for premature replacements.

Social Responsibility: Sustainable conveyors also consider social aspects, including worker safety. Manufacturers should prioritize the well-being of their employees, provide safe working conditions, and not only adhere to industry safety standards when designing conveyors, but identify ways to exceed these whenever possible. Dynamic Conveyors are simple to operate and maintain and are designed with operator safety being a top priority.

End-of-Life Management: Sustainable conveyor manufacturing includes planning for the end-of-life of conveyors. This involves designing for easy disassembly and the ability to be recycled. Dynamic Conveyor systems have been working in the manufacturing industry for over three decades. Their longevity contributes to the low total cost of ownership. If Dynamic Conveyors get taken out of service, most of the materials used in their construction are recyclable bringing the product full circle.

By considering these elements of sustainable conveyors, manufacturers can reduce their environmental footprint, conserve resources, enhance operational efficiency, and contribute to a greener more sustainable future.

Looking for sustainable conveyor solutions to automate your processes while also having a positive impact on the environment? We at Dynamic Conveyor stand ready to serve you. Contact us.