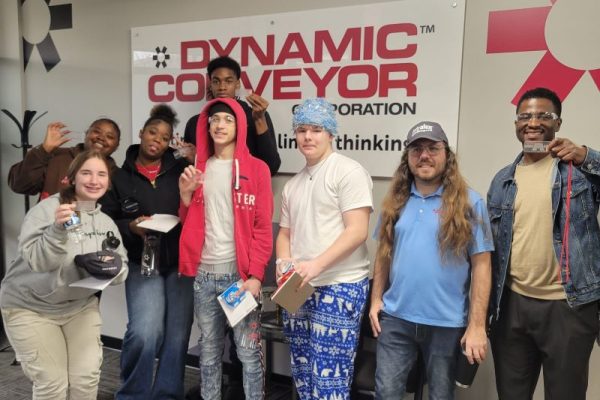

Manufacturing Week 2024 brought a vibrant energy to our facility as students from Muskegon Community Education Center joined us to explore how conveyors are made and discover what it takes to build a career in manufacturing.

The visit was designed to give students a real-world glimpse into the processes and skills involved in creating quality conveyance equipment.

Introducing the Next Generation of Innovators to our Company

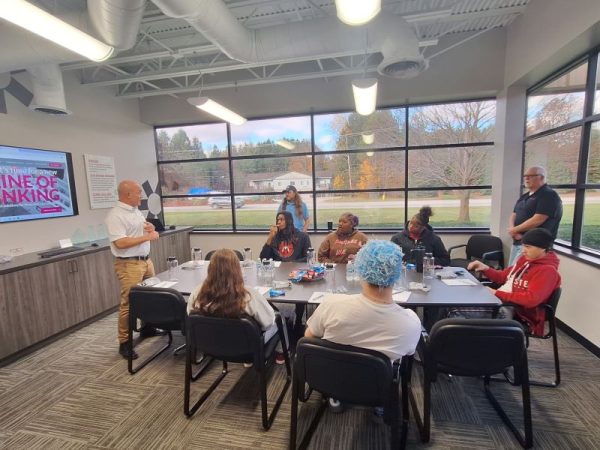

We started Manufacturing Week with the President of Dynamic Conveyor, Jordan Musselman, introducing the students to our company, explaining our commitment to producing innovative, modular, and sustainable conveyor solutions that meet the demands of various industries, from food, general manufacturing and packaging to parcel.

We shared that we’re more than just a manufacturer; we’re a company that invests in people. To inspire the students, we highlighted our employees who began on the production floor, gaining valuable experience in assembly or CNC machining, and then advanced to roles in production, engineering and management. These employees spoke with the students about their current careers and their journey to them demonstrating the growth potential within our organization and in manufacturing.

A Hands-On Experience

From the start, students rolled up their sleeves and dove into the hands-on activities we had prepared. Their journey began with CAD (Computer-Aided Design), where they explored the design phase of conveyor manufacturing. Understanding CAD software gave them a sense of how initial concepts turn into precise, digital blueprints—a crucial step before any materials are cut.

From the start, students rolled up their sleeves and dove into the hands-on activities we had prepared. Their journey began with CAD (Computer-Aided Design), where they explored the design phase of conveyor manufacturing. Understanding CAD software gave them a sense of how initial concepts turn into precise, digital blueprints—a crucial step before any materials are cut.

Moving from digital design to physical creation, the students headed over to our CNC Router (Computer Numerical Control) machining area. Here, they observed how these complex machines transform raw materials into the precision parts required for conveyor systems. Students learned about the importance of accuracy and saw the impressive speed at which CNC machines operate.

The grand finale was the conveyor assembly activity, where students put together a small conveyor unit. Under the guidance of our production team, they had a chance to apply what they’d learned about CAD and machining. They saw how each piece fits together and felt the accomplishment of turning several parts into a functional conveyor.

Learning Skills for a Rewarding Career

Throughout the day, we discussed with students the various skills that are key to a successful career in manufacturing, including CAD design, CNC operation, mechanical assembly, problem-solving, and teamwork. It was exciting to show them how these skills come together to produce the high-quality, low-maintenance equipment used across industries and a successful career in manufacturing.

Inspiring the Future

For many of these students, it was their first time inside a manufacturing plant, and we were thrilled to see their enthusiasm and curiosity. We hope that this experience sparked an interest in manufacturing careers and gave them insight into the opportunities available in engineering, production, and industrial technology.

As a company, we’re committed to supporting educational initiatives that inspire the next generation of production and engineering workforce, and Manufacturing Week was a wonderful reminder of why we’re passionate about our work. We look forward to continuing this tradition and seeing the impact it has on young minds eager to shape the future of manufacturing.

Considering a career in conveyor manufacturing or engineering? Explore exciting opportunities to join our team! From hands-on production roles to innovative engineering positions, we’re looking for driven individuals eager to shape the future of conveyor technology. Check out our current job openings and see where you can make an impact.

- SNAXPO25 Recap: Snack Industry Trends and Insights - April 6, 2025

- Modern Conveyance and Automation in Food Manufacturing - March 21, 2025

- Dynamic Conveyor and Muskegon Middle School: A Collaborative Journey in Design Thinking - February 17, 2025