Doing the research for a new belt conveyor system can be a daunting task: Should you stick with a traditional fixed system or is it time to upgrade to a modular conveyor system? The following checklist can help you determine what type of belt conveyor system is most suitable for your parts conveying applications:

Doing the research for a new belt conveyor system can be a daunting task: Should you stick with a traditional fixed system or is it time to upgrade to a modular conveyor system? The following checklist can help you determine what type of belt conveyor system is most suitable for your parts conveying applications:

-

Portability

Determine whether or not the conveyor will be needed for more than one process or at more than one location. Fixed metal conveyors are heavy and not easily moved. Plastic modular conveyors are lightweight and can be rolled from one plant to another or from one line to another. If you require quick access to machinery for servicing or changeovers, modular conveyors can be easily moved out of the way.

-

Ease of Belt Conveyor Repair

Mishaps can shut down a production line for a long period of time. Damaged conveyors, belts and accessories can be time-consuming to replace. Look for conveyor systems that can be repaired quickly and easily without specialized labor. Also consider conveyor belt design. If belts constructed of interlocking links are damaged, the damaged sections can be replaced within hours instead of days or weeks.

-

Access to Replacement Parts

Timely access to replacement parts is crucial for production uptime. Choose a supplier that has replacement units and components on hand and can deliver them within a few days or overnight if needed. Or choose a belt conveyor system that allows you to stock standardized replacement modules or accessories.

-

Flexibility

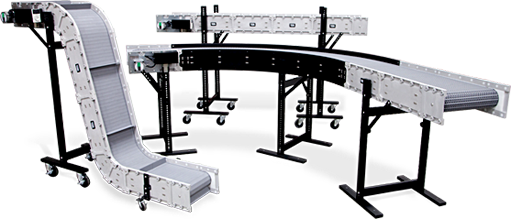

If you need to retool a production line quickly to meet deadlines, make sure that your belt conveyor system can be easily reconfigured. A modular system with standardized modules in a range of sizes and shapes provides agility. Using portable conveyor modules to customize conveyor lines may also enable users to fine-tune product lines to fit confined cell spaces.

-

Ease of Maintenance

Maintenance and uptime can affect productivity. Determine what type of maintenance your new conveyor system will need. Consider a self-lubricating system. Belting on traditional conveyors, such as PVC belting, requires frequent alignment and can be difficult and time-consuming to install and service.

-

Belt Conveyor Configuration Options

Conveyor systems should go wherever you need them to go. Make sure your new belt conveyor system includes configuration options like turns and inclines/declines. Modular systems should offer an array of accessories and specialized application modules that integrate with other modules to provide configuration latitude, dependable performance, and cost savings.

Click to see the benefits of a modular conveyor system

Stay informed by Subscribing to our E-News

- Boosting Efficiency with a Robotic Pick and Place Conveyor Solution in Plastics Manufacturing - April 18, 2025

- SNAXPO25 Recap: Snack Industry Trends and Insights - April 6, 2025

- Modern Conveyance and Automation in Food Manufacturing - March 21, 2025