One of our food manufacturing clients was looking for automation solutions to bring efficiency and precision to their production line while maintaining high-quality standards. Find out about what their challenges were and how Dynamic Conveyor created a customized automated conveyance system for their operations.

Challenge

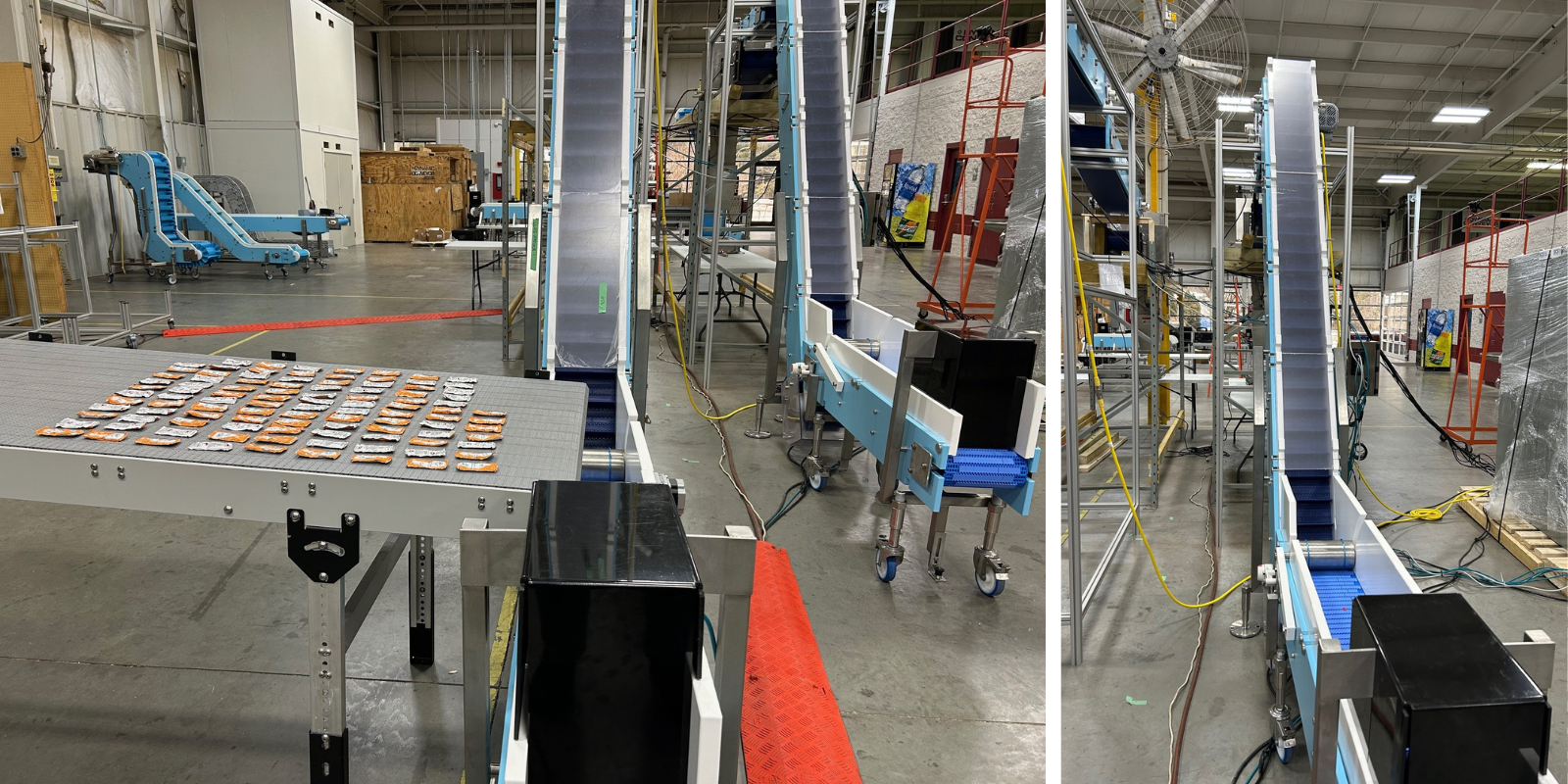

A portion pack and fulfillment food manufacturer needed their production line to move portion packs from machines in a washdown environment to a box filling system in a separate packaging room.

Solution

Our solution provided conveyance from the portion pack machines through to a separate packaging room to a chute feeding empty boxes. The turnkey automation system includes conveyance, leak detection, metal detection, vision counting, accumulation, and ultimately box filling to a target count at rates up to 720 units per minute. The system accommodates a variety of pack sizes and weights and provides for quick changeovers that keep production running efficiently.

Results

This solution is a modern, automated conveyance system to improve efficiency for the food manufacturing industry. The system provides efficiencies by way of increased throughput, reduced labor costs, count accuracy, reduced error and increased product quality. If quality issues were detected the integrated controls system will shut down the conveyor line.

Join the countless success stories with our Food Processing and Packaging conveyor solutions! Upgrade to a modern, durable system designed to enhance manufacturing efficiency, minimize waste, and maximize productivity. Let Dynamic Conveyor help you find the perfect solution—contact us today!

- Modern Conveyance and Automation in Food Manufacturing - March 21, 2025

- Dynamic Conveyor and Muskegon Middle School: A Collaborative Journey in Design Thinking - February 17, 2025

- Upgrading 30 Years of Reliable Conveyor Performance for a Souvenir Manufacturer - February 3, 2025