Collaboration with customers is an essential element of Dynamic Conveyors custom conveyor design process. Custom conveyor design involves creating unique systems tailored to the specific needs of a customer’s operation. This process requires extensive communication and collaboration between the customer and Dynamic Conveyor. Because the design process involves multiple stakeholders with different expertise and perspectives, a collaborative approach ensures that all stakeholders have a voice in the design process and that the final design meets expectations of the customer and delivers the results they need.

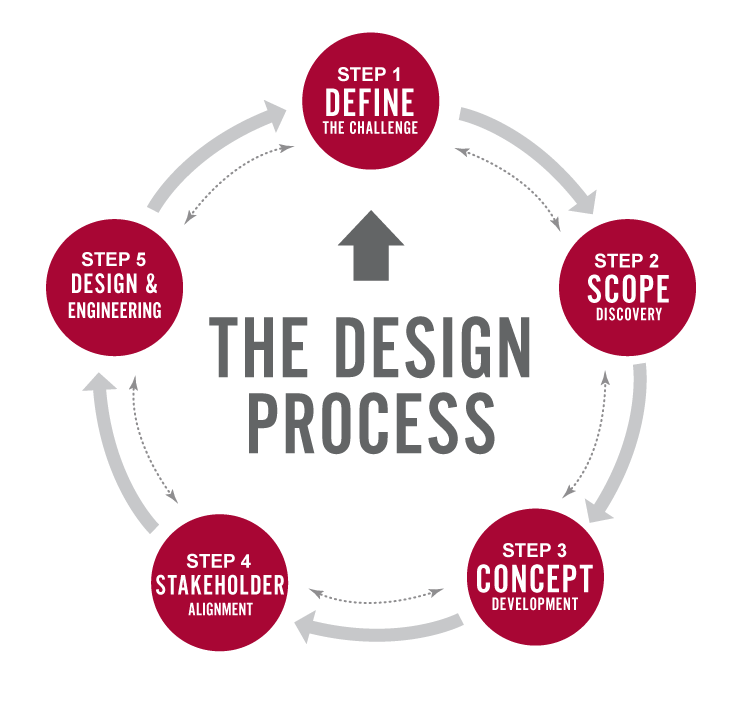

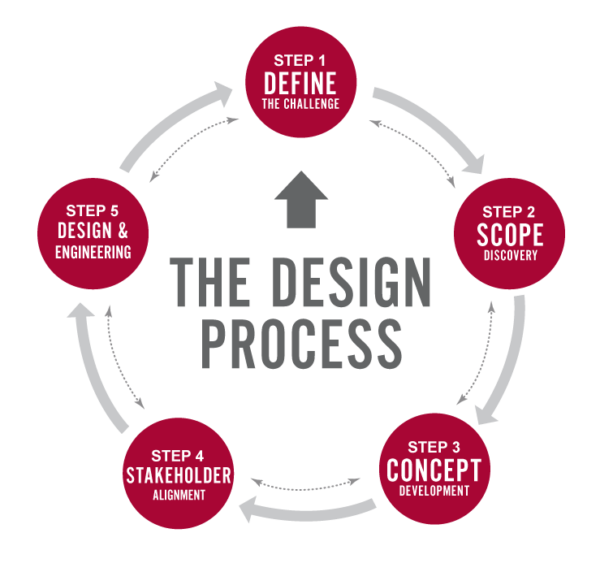

A good design process is a systematic approach to creating effective and successful designs. It involves a few steps that our sales team and Applications Engineers walk through with the customer to ensure that they understand the problem at hand, explore multiple concepts, and arrive at a well-thought-out conveyor design that meets the requirements and objectives of the project.

When engineering automatic conveyor systems at Dynamic Conveyor, we collaborate with the customer at each of these steps in our process:

Step 1 – Define the Challenge

Step 2 – Scope Discovery

Step 3 – Concept Development

Step 4 – Stakeholder Alignment

Step 5 – Design & Engineering

Here are some of the key reasons why we feel collaboration is important in custom conveyor design:

Understanding customer requirements: By collaborating with the customer, the applications engineering team can gain a deeper understanding of the specific requirements and needs. This can include factors such as the type of product being conveyed, the desired throughput, the layout of the facility, and any specific safety or regulatory requirements. By incorporating this information into the design process, the final conveyor system is more likely to meet the customer’s needs and expectations.

Leveraging expertise: In custom conveyor design collaboration, there are often multiple stakeholders involved, on both the customer’s and Dynamic Conveyor’s teams. The customer stakeholders can include all or some of these roles: engineering, purchasing, maintenance, production. By collaborating, each stakeholder can bring their unique expertise to the table and contribute to the design process. For example, the customer usually has specific knowledge of their facility layout or production processes, while our engineers will have expertise in conveyor system mechanics and design principles.

Optimizing design: Collaborating with customers can help optimize the design of a custom conveyor system. For example, the customer may have specific constraints or requirements that need to be considered, such as space limitations or regulatory compliance. By working together, the design team can identify potential trade-offs and optimize the design to meet these requirements while still achieving the desired throughput and functionality.

Building trust: By collaborating with customers, the teams can build trust and establish a strong working relationship. This can be particularly important in custom conveyor design, where the customer is often investing significant resources in the project. By involving the customer in the design process, they can see that their needs and requirements are being taken seriously, which builds trust and confidence in the final product.

One of the key benefits of collaboration is that it ensures that the customer’s needs are accurately understood and incorporated into the design process. By working closely with the customer, Dynamic Conveyor can identify the specific requirements of the operation and ensure that the conveyor system meets those needs.

Collaboration can also help to identify potential issues or challenges that may arise during the design and implementation process. By involving the customer in the design process, Dynamic Conveyor can gain valuable insights into the operation and identify any potential challenges that may need to be addressed. This can help to minimize delays and ensure that the system is designed and installed correctly the first time.

In addition to ensuring that the system meets the customer’s needs, collaboration can also help to build a strong relationship between the customer and the consultant. By working closely together, the customer and Dynamic Conveyor’s engineering team can develop a rapport and a mutual understanding of each other’s needs and goals. This can help to build trust and establish a long-term relationship that can lead to future collaborations and projects.

Finally, collaboration can help to ensure that the final system is both functional and meets the planned budget. By involving the customer in the design process, Dynamic Conveyor can identify ways to optimize the system for efficiency and reduce costs where possible. This can result in a conveyor system that not only meets the customer’s needs but also provides a strong return on investment and a low total cost of ownership.

In summary, collaboration is critical to successful custom conveyor system design. By working closely with the customer, the Dynamic Conveyor team can ensure that the system meets the customer’s needs, identify potential issues, build strong relationships, and optimize the system for efficiency and cost-effectiveness.

If you have an operational challenge and you wonder if conveyance could be a solution, contact us to start the collaboration.

- Boosting Efficiency with a Robotic Pick and Place Conveyor Solution in Plastics Manufacturing - April 18, 2025

- SNAXPO25 Recap: Snack Industry Trends and Insights - April 6, 2025

- Modern Conveyance and Automation in Food Manufacturing - March 21, 2025